Brief Introduction

At Spark Carbon, quality is the top mission for our operation, our

production starts from choosing the best raw material from domestic

and abroad to ensure the best quality from the beginning, our

petroleum coke is from CNPC Fushun, needle coke is from Conoco

Phillips 66 and Mitsubishi. We possess sophisticated manufacturing and

inspection equipment, provides 100% inspection and reporting on each

product delivered to customers

Graphite Electrode Production Process

-

STEP 01

High quality Needle coke or petroleum coke is calcined,

crushed and screened into proper sizes for production

-

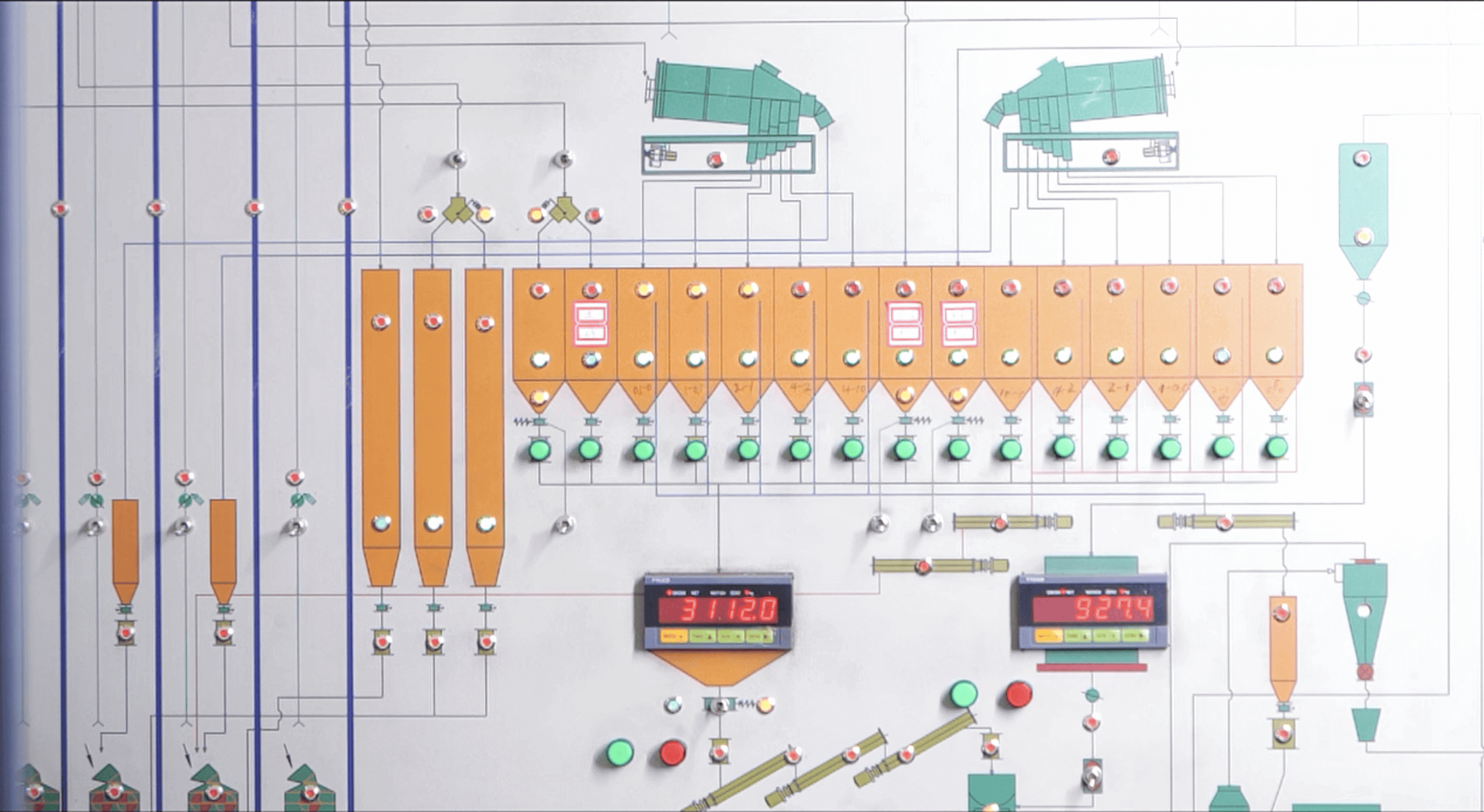

STEP 02

Automatic Dosing System

Calcined petroleum coke and needle coke are mixed with pitch

in controlled proportion via our automatic dosing system

-

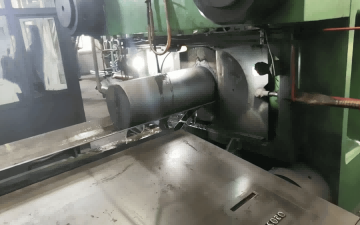

STEP 03

3500 ton Horizontal Extruder

The above mixed paste is extruded into green electrodes.

-

STEP 04

Primary Ring Baking Furnace 32 Chamber

Green electrodes are primary baked in our ring baking furnace

to remove the volatile matter.

-

STEP 05

High Pressure Impregnation Tank

Primary baked electrodes are impregnated with special pitch to

increase the density and strength.

-

STEP 06

Secondary baking-Tunnel Kiln

Impregnated electrode are put into Tunnel kiln for secondary

baking to coke the pitch

-

STEP 07

DLW Graphitization Furnace

Baked electrodes are then heated up to 2800-3000 C in

lengthwise electric resistance furnaces to convert carbon to

graphite.

-

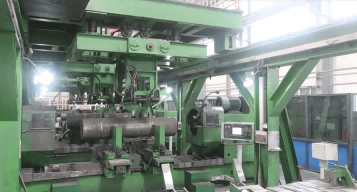

STEP 08

CNC Machining line

Electrodes and nipples are machined within well-defined

tolerances on automatic machine line are machined in required

diameter and matching end sockets to accept threaded nipples.

-

STEP 09

Quality Inspection